RFI and EMI Shielding

Radio Frequency Interference (RFI) shielding is often used specifically in applications with high electromagnetic interference emissions or sensitivity such as military displays and medical equipment.

Optical Filters are specialists in Electro Magnetic Interference (EMI) and Radio Frequency Interference (RFI) displays shielded windows, and windows with micro-etched mesh, touch screens, ITO coatings, and woven wire mesh.

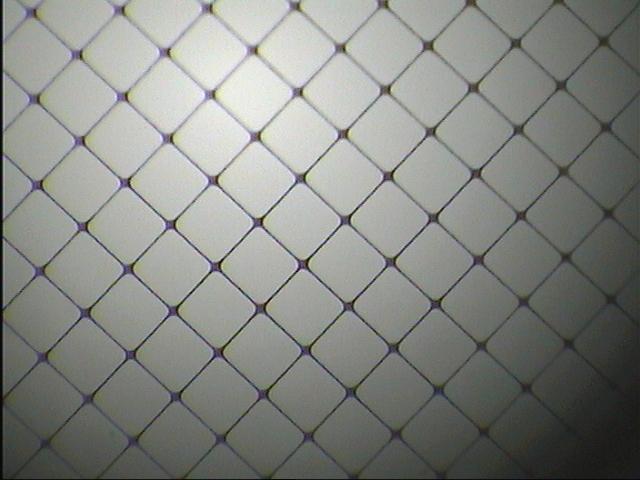

EmiClare® MicroMesh®

EmiClare is an unconventional mesh specifically designed for optical clarity without compromising the Electromagnetic Interference (EMI) shielding efficacy. A perfect photo-etched highly conductive grid, it is the name for optical clarity without EMC compromise. With a range of micro-replicated conductive grids, woven wire mesh, and conductive coatings, EmiClare is designed for allowing optical clarity without Electro-Magnetic Compatibility (EMC) compromise. The shielding also makes your display or touchscreen Radio Frequency Interference (RFI) compliant. Ideal for display sizes up to 60", Micromesh offers the optimal combination of high shielding attenuation and light transmission available.

EmiClare® Sigma

A general-purpose EMI shielded polycarbonate window featuring woven wire mesh optimised for electronics displays. Available with non-glare or hard coated surface finishes.

EMI-ITO Coated Glass

High transmission conductive coatings available from stock for quick cost-effective availability.

EmiClare TCF

EmiClare TCF is a low resistance, electrically conductive, silver alloy coated, optically clear polyester EMI/RFI shielding film. The combination of high visible light transmission, near neutral colour, infrared heat rejection, and low electrical resistance make EmiClare TCF an ideal EMI/RFI shield for electronic displays, touchscreens, and membrane switch panels requiring moderate shielding effectiveness and high-quality optical properties. This thin film is a clear choice for integration into optical stacks and displays.

EmiClare TCF is a replacement material to the discontinued EMI-ITO15 coated film.

Woven Wire Mesh

Blackened woven fine wire mesh for shielding windows, apertures, and displays. Available in stainless steel or copper substrates.