Research, Testing, and Development

With our technical expertise and strong R&D resource, we have succeeded in designing our products for a wide variety of both commercial and defence projects throughout the world. Our experienced team is available to offer information and advice on all aspects of the window design.

Proprietary In-house R&D

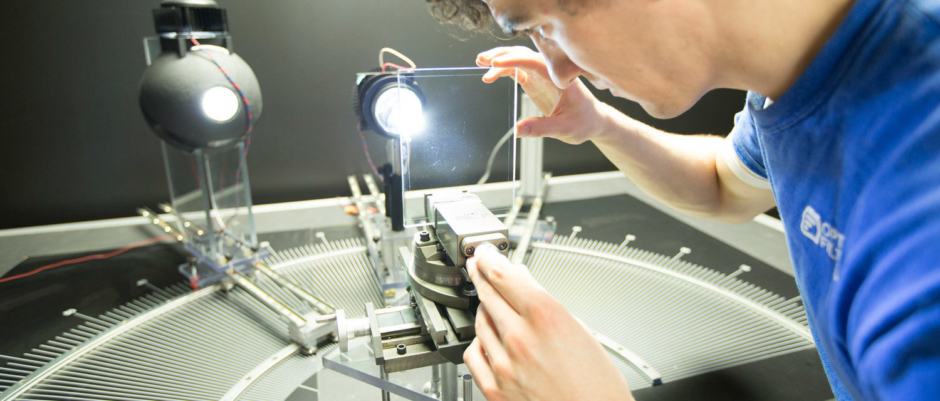

Dedicated research and design facilities enable the company to deliver responsive, technically advantageous solutions to meet precise customer requirements. Quality assurance is a cornerstone of our approach, and Optical Filters is an ISO 9001:2008 certified company. The company’s in-house laboratory offers a broad range of analytical services. Capabilities include optical measurement, environmental cycling, and material performance testing.

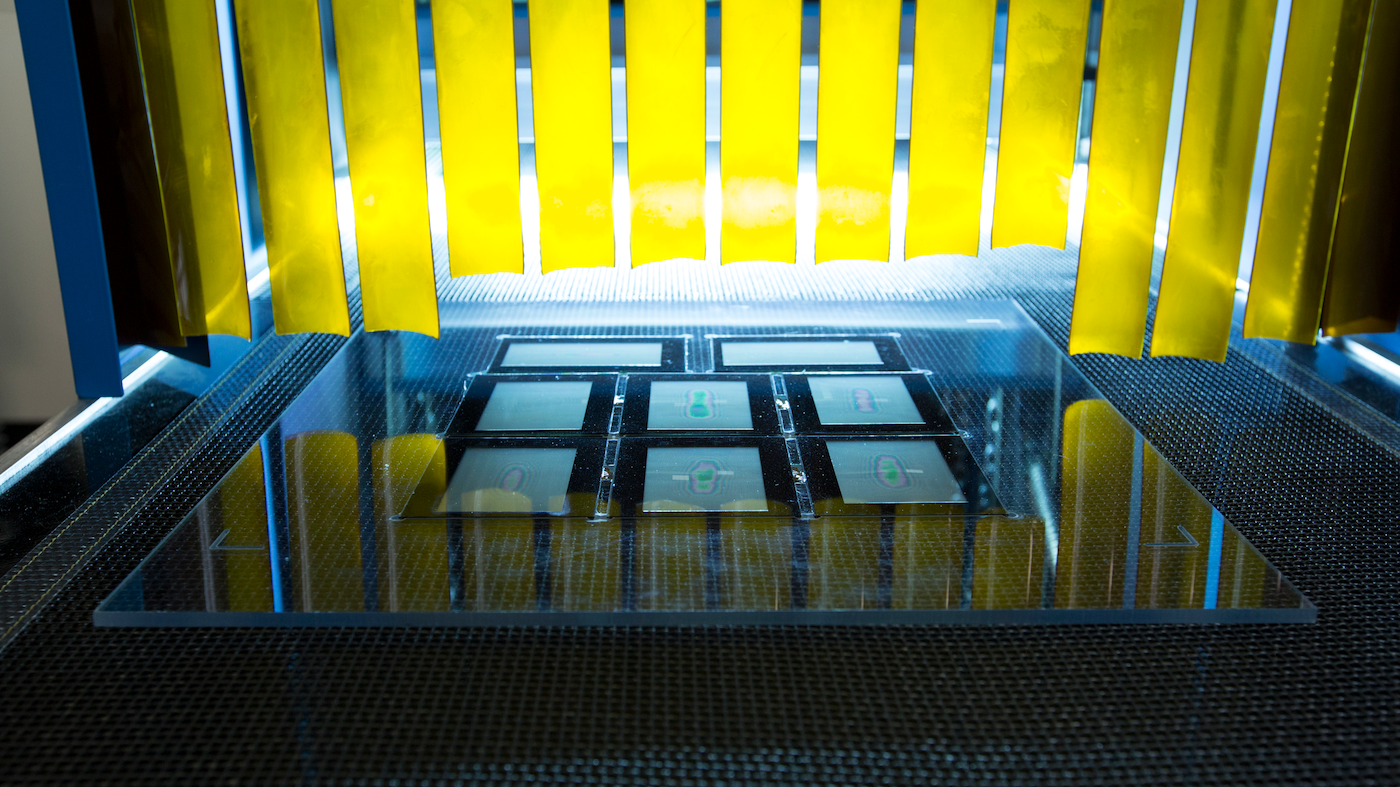

New product development is a priority at Optical Filters, a strategy that ensures the application of advanced materials and processes for optimizing product performance. Innovations such as the development of our unique Vizbond™ wet bond, a high-volume, high-yield system for bonding delicate components such as LCDs, and the second generation of MicroMesh™ (MM2), offering improved light transmission and EMI shielding that is superior to ITO coatings for shielded display and touch screens, are evidence of the company’s commitment to creating more effective and economical display solutions for its customers.

Refining manufacturing processes

Continuous quality improvement measures at Optical Filters are also concentrated on process development. The company’s class 100 and 1000 assembly environments integrate custom contamination control features to meet the most demanding quality requirements. And our skilled operators are well versed in material handling protocols.

Optical Filters’ engineering team has substantial knowledge of products and processes and works closely with customers to create optimum designs for their systems. Prototypes can also be developed to serve as models for optical filter performance to meet customer specifications.

Optical Filters building and testing a stronger lighter cover glass to withstand repeated impact strikes. Using a combination of dry lamination adhesives and toughened glass layers a heated EMI shielded electronic display glass was engineered and proven to pass boot strike tests. We can complete drop ball testing of cover glass and bonded displays.